- Home Page

- About US

-

Our Products

- Stitching Wire

- Galvanised Stitching Wire

- Narrow Flat Stitching Wire

- Rust Proof Galvanized Stitching Wire

- Broad Flat Stitching Wire

- Round Stitching Wire

- Box Stitching Wire

- Corrugated Boxes Stitching Wire

- Stitching Wire

- Stitching Wires

- Baling Wire

- Book Stitching Wire

- Premium Stitching Wire

- Electroplated Zinc Stitching Wire

- Flat Stitching Wire

- Galvanized Iron Wire

- Binding Wires

- Black Baling Wires

- PVC Coated Wire

- Black Annealed Wires

- Spring Steel Wires

- Staple Wires

- MIG Welding Wire

- High Carbon Steel Wire

- Brass Wire

- Copper Steel Wire

- Stitching Wire

- Contact Us

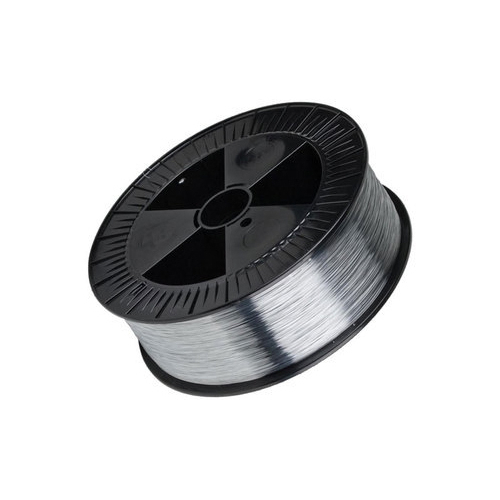

Electroplated Zinc Stitching Wire

Product Details:

- Conductor Type Solid wire

- Temperature Safe for normal room temperature usage

- Cable Length Depends on coil size (subject to gauge used)

- No Of Core Single core

- Product Type Electroplated Zinc Stitching Wire

- Material Electroplated Zinc Coated Steel

- Function Binding and stitching

- Click to View more

X

Electroplated Zinc Stitching Wire Price And Quantity

- 2-3 Ton

Electroplated Zinc Stitching Wire Product Specifications

- Steel core with zinc plating

- Metallic silver

- Standard coil length, typically 10 kg per coil (length varies by gauge)

- Single core

- Depends on coil size (subject to gauge used)

- Solid wire

- Electroplated Zinc Stitching Wire

- Typically between 0.56 mm to 0.71 mm, depending on wire gauge

- Electroplated Zinc Coated Steel

- Safe for normal room temperature usage

- Suitable for manual and automatic stitching machines

- Available in various gauges (commonly 22, 24, 26 SWG)

- Stitching books, magazines, cartons, and packaging

- Binding and stitching

Electroplated Zinc Stitching Wire Trade Information

- 100000 Ton Per Week

- 3-4 Week

Product Description

Made of carbon steel, electroplated Zinc Stitching Wire is reckoned for its optimum strength. Its tensile strength ranges between 350 N/mm2 to 600 N/mm2. This industrial wire has zinc coating on its surface to avoid rust formation. Electroplated Zinc Stitching Wire has been manufactured by using quality approved raw materials. It is wear and abrasion proof. Moreover, it can be handled easily. Its quality has been checked on the basis of its service life, utility, surface finish, dimension, coating thickness and design.

Technical specification

|

Brand |

National Wire |

|

Surface Treatment |

Zinc Coated |

|

Material |

Carbon Steel |

|

Usage/Application |

Industrial |

|

Color |

Silver |

|

Tensile Strength |

350-600 N/mm2 |

|

Thickness |

0.40-16 mm |

Corrosion-Resistant Performance

The uniform electroplated zinc coating creates a resilient barrier against corrosion and oxidation, significantly extending the wires shelf life, even in humid environments. This makes it an excellent choice for packaging materials that need to be stored or shipped long distances, ensuring durability throughout its lifecycle.

Exceptional Binding Strength and Versatility

With its high tensile strength, the wire offers robust and secure binding suitable for a variety of applications, such as stitching books, magazines, cartons, and export packaging. Its compatibility with different stitching machinesmanual, semi-automatic, and automaticincreases its utility across multiple industries.

Safe, Lead-Free Material for Sensitive Applications

Manufactured without lead, the zinc coated stitching wire is safe for use in packaging applications involving food and pharmaceutical products. This safety assurance broadens its scope for manufacturers requiring compliance with stringent health and safety regulations.

FAQs of Electroplated Zinc Stitching Wire:

Q: How does the electroplated zinc coating benefit the stitching wire?

A: The electroplated zinc coating provides a uniform layer that greatly increases the wires resistance to corrosion, ensuring longevity and maintaining its strength and appearance even under challenging storage or shipping conditions.Q: What types of packaging and stitching machines are compatible with this wire?

A: The wire is engineered for maximum versatility, making it suitable for manual, semi-automatic, and fully automatic stitching machines, accommodating a wide range of industrial and commercial binding processes.Q: When is it recommended to use this lead-free zinc stitching wire?

A: This wire is particularly recommended when packaging food items, pharmaceuticals, or any materials requiring safety from lead contamination, as well as when durability in corrosive environments is necessary.Q: Where is the stitching wire commonly used in terms of applications?

A: Electroplated Zinc Stitching Wire finds common usage in binding books, magazines, cartons, and packaging boxesespecially in industries that prioritize strength and product integrity during handling and transport.Q: What is the standard packaging specification for this stitching wire?

A: Typically, the wire is packed in coils or spools weighing about 10 kg each, although coil sizes and lengths may vary depending on the gauge and client requirements.Q: How does the manufacturing process ensure product quality?

A: The wire is produced following strict industry standards for electroplating and material strength, ensuring a consistent zinc coating, smooth finish, and the required high tensile strength for reliable stitching and binding.Q: What are the advantages of using a steel core with zinc plating for stitching wire?

A: A steel core offers excellent mechanical strength and durability, while the zinc plating acts as a protective shield against environmental factors, resulting in a product that is both strong and resistant to corrosion.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email